Table of Contents

TYM tractors are built for performance in both arable and non-arable fields. Because they are made from high-quality materials like aluminum and steel alloy, they can withstand harsh farming conditions without wearing down quickly. Their engines are also powerful enough to perform multiple tasks on a single pass over the field – eliminating the need for multiple passes through the same area.

TYM’s products include a wide range of agricultural machinery, including tractors (25-100hp), combines (30-100hp), sprayers (30-100hp), and accessories such as air conditioners and hydraulic hoses, etc.

TYM tractors come in several different models, including the TYM-50 and TYM-70. These tractors are primarily used to pull plows, tillers, and other agricultural implements. However, several common problems with these machines can cause them to stop working correctly or even break down completely.

TYM Tractor Problems

If you notice a problem with your TYM 494 tractor, you should first stop using it immediately. The best way to handle an issue like this is to contact a service technician at your local dealer or dealership. If you have any problems with your TYM 494 tractor, you must take care of them as soon as possible so that they don’t lead to more severe problems later on.

Here are some common problems that can occur with the TYM 494 tractor:

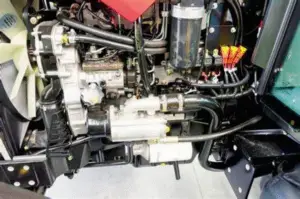

Engine overheating: This usually indicates a problem with oil or coolant levels or excessive engine wear due to improper maintenance or overuse.

Excessive vibration: This could be caused by bad bearings or tires needing replacement.

Leaking fluid – Oil leaks should be repaired immediately because they can cause critical damage to internal engine components if left unchecked.

TYM Tractor Electrical Problems

The TYM tractor is a front-wheel drive model powered by a 163cc engine. The engine is air-cooled and comes with a recoil start. The transmission on this model is a manual type with two speeds forward and one reverse.

The TYM tractor has several electrical problems that can occur, such as:

- The battery will not hold a charge even after charging it for several hours.

- The battery will charge, but when you turn the key to start the tractor, nothing happens, and the lights dim out immediately after turning on the key.

- The battery will not charge at all, no matter how long you leave it connected to your charger or how many times you jump-start it from another vehicle or use jumper cables from another vehicle to jump-start it from another vehicle so that you can get home without being stranded in the middle of nowhere with no way of getting help if something goes wrong with your vehicle and no way of getting home because your battery is dead!

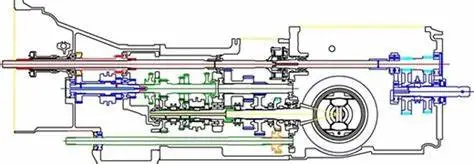

TYM Tractor Transmission Problems

Tym Tractors problems range from transmission problems to engine issues. RepairPal generates both national and regional coverage for your Tym Tractors.

The average cost to repair the transmission is between $1,000 and $1,500. The national average cost for transmission repair is $1,307.

Common problems with the transmission in TYM tractors include:

- A bad leaking seal can lead to fluid loss or fluid running out of the tractor. When shifting gears, a bad seal can also cause a grinding or whining sound inside the transmission.

- The filter may become clogged due to dirt, sand, or other debris in the oil, causing it not to circulate properly, which could lead to excess heat build-up and damage the transmission.

- A shift solenoid may be defective or need cleaning and adjusting, which could cause it not to shift properly from one gear to another.

TYM Tractor Hydraulics Troubleshooting

Hydraulic problems are the most common problems with tractors. Most of these problems can be traced back to a leak in the hydraulic system.

- Check for leaks at fittings and hoses. If a leak is found, repair it as necessary.

- Check for blocked filters in the hydraulic circuit. Clean or replace as required.

- Check for damaged O-rings on hydraulic cylinders, valves, and seals (if fitted). Replace if necessary.

- Check for damaged gaskets on hydraulic outlets of pumps (if fitted). Replace if necessary.

- Check that all hydraulic hoses are connected to their respective ports and use the correct hoses only (see diagrams in the workshop manual). Use a pressure gauge to check if there are any leaks in the system or to see if there is adequate oil in the reservoir tanks before starting work on any parts of your tractor that use hydraulics, such as lift arms,

- A hydraulic system must have sufficient oil at all times, so check that you have enough hydraulic fluid (oil) in your reservoir tanks before starting work on any parts of your tractor that use hydraulics, such as lift arms, implements, etcetera.

- Suppose your tractor has been extensively used or worked under heavy loads for long periods. It may be necessary to occasionally top up the oil level with fresh fluid, as this will help keep all moving parts lubricated and functioning properly.

- If you need to learn how much fluid is in there or whether it is contaminated, drain out what you can and refill with new fluid.

TYM Tractor Clutch Problems

The clutch is the most essential part of any tractor. It is used to engage and disengage the engine from the transmission. The clutch on a TYM Tractor is usually made up of several parts that can fail over time. This can cause your tractor not to accelerate correctly, or it can prevent you from being able to shift gears. The following are some signs that your tractor’s clutch may need to be replaced:

- Slipping or slipping and grinding when shifting gears

- “Noise” or “grinding” while accelerating

- The engine stalls when trying to move forward or backward

TYM Clutch Engages To Transmission

TYM tractors have a clutch that engages the engine to the transmission. When this clutch wears out, it can cause problems with your tractor. If you try to start the engine without engaging the clutch, it will pop back at you when you turn the key. This is because the engine is not connected to the transmission and has no power going to it, so it pops back at you as soon as you turn on the key with no oil pressure due to the lack of engagement of clutch plates inside the flywheel housing!

TYM Clutch Slip After A While

Another problem with this type of clutch is they tend to slip after a while, which causes a lot of noise while driving down roadways or even just going around the yard doing chores outside! If you hear excessive noise from under the hood (hood cover) while driving or turning corners hard, your clutch needs attention!

TYM Tractor Steering Problems

The steering mechanism on a tractor is fundamental when it comes to the overall performance of the machine. If you have any problems with your tractor’s steering, it can lead to several issues that could be very costly. Here are some common steering problems that you may experience with your Tym Tractor:

Steering wheel not working properly:

This is one of the most common problems with tractors, and if you are having trouble with your steering wheel, you need to get it checked out immediately. If something is wrong with your complex system, it will not be able to work correctly, and this can cause issues down the line.

Steering gears not working correctly:

If something is wrong with your steering gears, this could also lead to serious issues. The gears are responsible for ensuring that your tractor moves in the right direction, and if they do not work correctly, this could lead to more problems in the future. Make sure that you get these checked out as soon as possible so that they do not cause any more damage in the future.

What To Consider If Steering Is Not Working?

If you are having trouble with your Tym Tractor steering, you should check out the following articles.

Tires Are Not Inflated

First, ensure your tires are inflated to the correct PSI rated for your vehicle. If they are not, they will wear out much sooner than they should, which can also cause problems with your steering. So ensure you keep up on tire maintenance and always have them checked and filled in when needed.

Upgrade Steering System

Secondly, if you have an older model of a Tym Tractor, it may be time to upgrade your steering system. Older models have a manual steering system which can be challenging to use, especially when turning sharply or backing up with heavy loads. A power steering system will make it easier to maneuver around obstacles or make sharp turns while driving forward or in reverse.

Alignment Of Your Front Wheels

Thirdly, check the alignment of your front wheels and the alignment of your rear wheels if applicable. If any of these wheels need to be aligned, this can cause problems with how well it steers and how easy it is to control this vehicle while driving it around town or on the farm property where it is used most often!

Why Is Engine Releasing A Bad Smell in TYM Tractor?

There are many different reasons why your Tym tractor may release a bad smell from its engine.

Leaky Radiator

The first reason behind releasing bad smells from your engine could be a leaky radiator cap or a faulty radiator cap seal. This happens due to overheating of the engine, which causes cracks in the radiator cap or causes leakage in the radiator cap seal, resulting in gas escaping out of the engine compartment while driving or idling. It will also cause very slow oil leaks, which can drain out all your oil reserves within minutes if left unattended for long periods of time without any maintenance work done on it by an experienced technician who knows how to deal with such kinds of issues.

Excessive Dust

The second reason can be due to excessive dust particles accumulating inside your engine, causing clogging of certain parts like air filters, fuel filters, etc., which reduces the flow of air and fuel into your engine, leading to overheating and subsequent emission of smoke from your vehicle.

Leaking Seals

The third reason behind releasing a bad smell from your engine may be leaking seals around oil pumps and gaskets around valve covers, which allow oil vapors to escape from these areas.

Why Doesn’t The Engine Start or Turn Over in TYM Tractor?

Tractor engines are designed to be very reliable, but sometimes problems do occur. The most common problem we hear about is that the tractor won’t start or turns over slowly. Here are some reasons why this may happen:

Fuel filter clogged – A clogged fuel filter can cause your engine to run rough or not start. This is usually caused by worn-out or broken fuel filters and should be replaced as soon as possible to avoid permanent damage to your engine. Replacing your fuel filter is a relatively simple job and can usually be done in less than an hour with essential hand tools and a little knowledge of how diesel engines work.

Low oil level: Keeping your tractor’s engine oil at the proper level is essential. If your engine oil is too low, it can cause severe damage to the engine. Check your engine oil level every time before starting and after each use. If you notice that the oil level is too low, add oil until it reaches the proper mark on the dipstick located on top of the engine block just below where the air cleaner attaches to the carburetor housing (or where ever else they are located on your specific model).

Low battery voltage: If your Tym has a weak battery or a bad alternator, it may need more juice to start up properly. This can cause stalling, lack of power, and other issues during acceleration. To fix this problem, charge your battery or replace it if necessary.

Bad spark plugs: Old or worn-out plugs can cause problems with starting up your Tym because they won’t ignite fuel properly during combustion, so air cannot pass through the engine effectively. To fix this issue, replace all 4 spark plugs with new ones (the correct type for your model).

Low compression: Low compression means there isn’t enough pressure in your engine to correctly compress air and fuel together to burn efficiently. This usually results in lost power, poor fuel economy, and rough idling conditions, among many other issues related to improper combustion.

Bad distributor cap/rotor – The distributor cap/rotor distributes electricity from the top of the engine down to each cylinder by turning inside a distributor shaft connected to the crankshaft. If this unit is not working correctly, it will cause poor performance and rough idling.

Is There an Unresponsive Brake System In TYM Tractor?

The brake pedal on a tractor is hard to press, but it should be firm. If your pedal is loose or the brakes don’t work, you may have a problem with the brake system. The hardest part of diagnosing and repairing a brake problem is locating the problem. You must troubleshoot the system until you find the faulty component.

Check for Leaks

The first thing to check for is leaks in your hydraulic system. Tractors use hydraulic fluid to apply brakes and other systems. If leaks are in your hydraulic system, you’ll need to replace them before testing anything else.

Brake Fluid Levels

If there’s no sign of leaks, check the fluid levels in your brakes by removing the cap from each reservoir and adding new fluid if necessary. Fill each reservoir until it reaches its maximum mark, then wait 15 minutes before checking again so that any air bubbles will work their way out of the system. Refrain from filling because this can cause problems and brake and fade when driving down hills or long distances without stopping.

Why Is TYM Tractor Causing Lighting System Issue?

The TYM tractors are a series of small tractors manufactured by the Tym Tractor Company. The company is based in China and has been manufacturing small tractors for over 30 years

There are several reasons why your TYM tractor may be experiencing issues with its lighting system:

The wiring Harness Is Connected Properly

The wiring harness may need to be properly connected to your tractor’s light bulbs or other electrical components. This can cause problems with your headlights, brake lights, or turn signals.

Wiring Harness Detached From Connections

The wiring harness may have detached from connections within your tractor’s engine compartment. This can cause problems with your headlights, brake lights, turn signals, and other electrical components like radios and air conditioners.

Headlight Bulb Issues

Your headlight bulb may not work correctly due to a poor connection between it and the wiring harness inside your tractor’s engine compartment. This can result in no light coming from either headlight on your tractor when you turn them on at night.

Why Is My TYM Tractor Overheating?

Overheating can be caused by many different things on your tractor. It could be something as simple as adding more oil or adjusting the belts on your tractor. However, you have already checked all of these things. Another cause of overheating on your tractor may need to be addressed immediately before further damage occurs to it or any other components on your tractor!

Clogged Radiator

The most common cause of overheating on a tractor is a clogged radiator. This can be caused by several factors, including coolant leaks, dirt and rust build-up in the cooling system, or even a clogged air filter. If you have recently replaced your radiator and still find that your tractor is overheating, you should check for other possible problems.

Tractor Is Not Used For Extended Periods

If your tractor has been sitting for an extended period without being started, it could be due to a clogged fuel filter or carburetor float bowl. These issues can often be fixed by cleaning the fuel system and carburetor.

Are TYM Tractors Good Quality?

Most people who own TYM tractors say they’re very happy with their purchase. They say the tractors are well-built and tough enough to last a lifetime of use on a farm or ranch. Some owners say they’ve had their TYMs for 10 years or more, and the only problems they’ve had were related to parts wearing out over time or being damaged by abuse while working on rough terrain. Others say they’ve never had any problems with their tires. Most owners report that their TYSs run very well and start quickly in cold weather or after sitting unused for months (which is essential in areas with long winters).

Are TYM Tractors Reliable?

TYM tractors are a good choice if you’re looking for an affordable, entry-level machine. The company has been around since 1987, and they have built a reputation for offering reliable products at a reasonable price.

TYM has also been known to offer excellent customer service as well.

Winding Up

During the life of your Tym Tractor with Perkins engine, it is inevitable that fundamental problems will develop. The following guide dissects the topics and troubleshoots them in detail to eliminate future issues.

Related Posts