Table of Contents

The John Deere 1025R tractor is a small-scale tractor for working on farms and light construction sites. The John Deere 1025R is equipped with a Yanmar engine, which runs at 3200 rpm, and can be used for tilling, plowing, and cultivating.

The John Deere 1025R tractor has a transmission that provides 8 forward gears and 2 reverse gears. This makes it easy to use in different terrains and conditions. It also has several implements to help with other tasks, such as tillage implements, plow point adapters, and cultivator shanks.

Best Features In John Deere 1025R

Engine In This Tractor

The engine in this tractor is a V-twin diesel engine that offers 55 horsepower and 205 foot pounds of torque. This can help you get the job done faster, especially when you have a lot of heavy equipment on board with this tractor.

Powerful Transmission

The transmission on this John Deere 1025R is also very powerful, offering up 16 forward gears and 2 reverse gears for maximum power transfer and performance when needed.

Cab Features

The cab features heaters and A/C vents, and windshield wipers, so if you get caught in bad weather conditions while working outside, you will have no problem getting back inside once you’re done with your current task at hand.

What Are The Common Problems And Solutions Of John Deere 1025r?

The following are some common problems and solutions related to John Deere 1025R:

Problem: The engine won’t start

Solution:

- Check the fuel supply and make sure it’s turned on.

- Make sure there is enough oil in the crankcase.

- If this doesn’t work, clean the battery terminals or replace them if necessary, then try starting the engine again.

Problem: Engine overheats when idling

Solution:

- Check that all fluid levels are normal (oil and coolant).

- Inspect belts for damage, wear, or leakage from pulleys; replace them if necessary.

- Check cooling fan operation; replace if necessary.

- Check radiator hoses for leaks or cracks; replace them if necessary.

Problem: Engine overheats when operating under heavy loads

Solution:

- Check that all fluid levels are normal (oil and coolant).

- Inspect belts for damage, wear, or leakage from pulleys; replace them if necessary.

- Check cooling fan operation; replace if necessary.

- Check radiator hoses for leaks or cracks; replace them if necessary.

Problem: Excessive oil consumption

Solution:

- Check that all fluid levels are normal (oil and coolant).

- Inspect belts for damage, wear, or leakage from pulleys; replace them if necessary.

- Check the cooling fan operation; replace if necessary.

- Check radiator hoses for leaks or cracks; replace them if necessary.

Problem: Excessive smoke from the exhaust

Solution:

- Check for a clogged catalytic converter, loose or misaligned exhaust manifold, or broken exhaust manifold gasket.

- Inspect the engine for damaged piston rings, worn valve guides, flexible valve cover gaskets, excessive carbon buildups, and worn valve stem seals.

- Inspect the fuel system for leaks and correct any.

Problem: Leaking engine oil

Solution:

- Check the oil level in the dipstick tube (oil should be within the FULL mark). If leaking is excessive, check for external leaks in the engine compartment by inspecting engine connections and oil filter housing for signs of leakage.

- Inspect the oil filter housing gasket for proper installation; replace the gasket if necessary.

- Inspect all hoses for cracks or leaks; replace them as necessary.

Problem: Noisy exhaust system

Solution:

Remove the muffler and inspect it for cracks or holes; repair or replace it as needed.

Problem: Engine stalls

Solution:

Check for air leaks in intake manifold gaskets or cracked intake manifolds; replace as needed. Inspect fuel lines for leaks at clamps, fittings, and connections; tighten clamps as required. Inspect injectors for proper adjustment and condition; replace them if necessary. Make sure the throttle linkage is working correctly.

Problem: The engine hesitates when accelerating

Solution:

- Check that all fluid levels are normal (oil and coolant).

- Inspect belts for damage, wear, or leakage from pulleys; replace them if necessary.

- Check cooling fan operation; replace if necessary.

- Check radiator hoses for leaks or cracks; replace them if necessary.

- Replace spark plugs with new ones of the same type number and gap setting as shown on your owner’s manual (if equipped with a distributor ignition system).

- While using an electronic ignition system, check for a spark at each coil wire terminal with a timing light while cranking.

Drive train failure:

Another common problem with John Deere 1025r is drive train failure which means that some issues with the transmission system or brakes may cause trouble for the operator while driving this tractor through challenging terrains or fields.

Steering Wheel Issues:

The steering wheel on the John Deere 1025R is known to break easily and require replacement. This problem can be caused by a faulty bearing in the wheel assembly or by hitting a large rock or pothole while driving. If your steering wheel is loose while driving down the road, immediately take your tractor to an authorized John Deere dealer.

John Deere 1025r Trouble Codes

| Trouble Codes | Solution |

| SHIFt to NEut | Neutral Switch OFF |

| SHUt Pto OFF | PTO ON |

| Pull CoiL FAult | Coil Open or Short to Ground |

| StArt CoiL FAUlt | Starter Coil Open or Short to Ground |

| EnGInE run | Crank Attempt |

| RIO_ON= | Mid PTO is disabled |

| RPEdAL SEnSE | Sensor Inputs NC and NO both at 12V or at Ground |

| PtO CoIL FAULt | PTO Coil Open or Short to Ground |

| RIGht Bulb Error | Bulb Open |

| LEFt Bulb Error | Bulb Open |

| EnGIne Error HEAt | Engine Coolant Above 112C/234F |

How To Operate A John Deere 1025r?

The John Deere 1025R has many safety features that make it easy to operate safely. These include:

- Foot-operated parking brake

- Three-point hitch system

- Hydrostatic drive system

The following are steps to operate this type of equipment:

- Place the transmission into neutral.

- Make sure the parking brake is set.

- Turn the ignition key to the “on” position (but do not start the engine).

- Put the clutch lever in 1st gear (if you use a manual transmission). If you have an automatic transmission, push down on the accelerator pedal and hold it down while you place the shift lever into 1st gear (or drive).

- Turn on your headlights if they are not already on, and let go of the clutch pedal slowly while keeping pressure on the accelerator pedal until you feel resistance from the engine (this can take up to 20 seconds). You should now be able to drive forward slowly or reverse slowly, depending on which way your tractor faced when you started this procedure.

John Deere 1025r Seat Problems

The John Deere 1025r tractor seat is designed for something other than comfort but to handle the weight. You’ll find that the seat is made of a hard plastic material that isn’t very comfortable when sitting down for long periods. The biggest problem with this type of material is that it doesn’t support your back very well, so if you’re like most farmers who spend hours in their equipment, this will cause back pain over time.

Weak or broken springs: When these springs break or become ineffective, they may not support you well enough while riding your John Deere 1025r. This can cause you to lose your balance and fall off the tractor, leading to severe injuries, including broken bones and concussions.

Broken mounting bolts: These bolts hold the seat firmly in place on your John Deere 1025r, so if they are broken or loose, then it may cause instability or even make it difficult for you to get off the tractor safely in case of an emergency such as fire or flood damage.

Bent brackets: Bent brackets could cause improper positioning of the seat belt buckle, which can cause chaffing or pinching of your skin while riding your John Deere 1025r, resulting in an injury.

Broken buckle: The seatbelt may break under regular use and cause injuries.

Incorrect adjustment: Improperly adjusted belts could lead to injuries if worn incorrectly.

John Deere 1025r Electrical Problems

The most common John Deere 1025r electrical problem reported is the battery cable connection.

Battery Cable Connection To Check

First, check the battery cable connections to see if they are corroded or broken. If so, clean them with sandpaper or a wire brush and apply dielectric grease to both ends of the cable where it connects to the tractor. If this does not solve the problem, you may need to replace the cables since they may be damaged beyond repair.

FAQs

Why Is My John Deere 1025r Not Moving?

If you are having trouble moving your John Deere 1025r, it may be for a few different reasons. You should first check the transmission fluid level and ensure it is complete. If this does not fix your problem, you need to check the engine oil level. Both of these things can cause your machine not to move forward or backward. Also, ensure that the tires have enough air in them. If they do not have enough air, they will not grip the ground properly and cause your tractor not to move correctly.

Is John Deere 1025r A Good Tractor?

The John Deere 1025r is a perfect tractor for those who need something more significant than what they would usually use for their daily farm chores on their property. It has plenty of power for anything that you require and can handle most of what comes its way without any problems whatsoever!

Why Is My Jd 1025r Engine Overheating?

The engine on the John Deere 1025r is a liquid-cooled, 4-stroke diesel engine. It is designed to run at an average temperature of about 140 degrees Fahrenheit (60 degrees Celsius). When your engine’s temperature gets too hot, it may cause damage to internal engine parts and components. The most common cause of overheating in this tractor is a malfunctioning thermostat. If you notice that your John Deere 1025r is overheating, then you should have it checked out by a mechanic before using it again.

Why Is My John Deere 1025r Not Starting?

John Deere 1025r engines are often temperamental when they need to be started more regularly. They need fuel and oil changes every so often, and they need to be started up at least once per week if they’re going to stay healthy and happy! If you still need to start your John Deere 1025r weekly, it could be difficult.

What Are The Causes Of Faulty Steering In Jd 1025r?

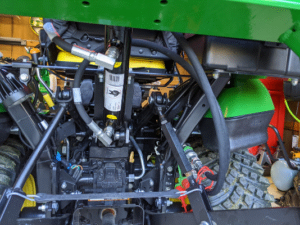

A hydraulic system controls the steering in JD 1025R. This system consists of a power steering pump, gearbox, steering cylinder, and control valve. The check valve is located in the power steering pump, preventing the oil from flowing back to the reservoir when the system is not working. The power steering pump supplies high-pressure oil through the pump shaft to the steering gearbox. The steering gearbox contains gears attached to your tractor’s wheels. If one or more of these components fail, you will experience problems with your tractor’s ability to steer correctly.

Why Is My Jd 1025r Battery Not Charging?

Your battery may not charge because it has become faulty or has been damaged by overcharging or short circuits. If this happens, you’ll need to replace the battery with a new one before driving again. You should also check that there are no electrical faults in your tractor before replacing the battery, as this could cause similar problems in the future.

Why Does John Deere 1025r Creep Forward?

When the John Deere 1025r creeps forward, it most likely means that there is a problem with the transmission. It could be a bent or broken shift fork, or it could be that the engine is not getting enough oil. If you cannot find anything wrong with your transmission, it may be time to take it to a mechanic for inspection.

Why Is John Deere 1025r Running Rough?

A running rough John Deere 1025r can mean many things. It could mean that your spark plugs are bad, or it could mean that your air filter needs replacing. If this is not the problem, you should take it to a mechanic for a proper diagnosis.

What Are John Deere 1025r Hydraulic Problems?

The John Deere 1025r has 1 reported issue with the hydraulics. We will address the top 3 problems below.

- First, the front axle shafts can break. This is due to a defective design of the axle shafts and the failure of the bearings. If this happens, you need to replace the axle shafts for your tractor to be operational again.

- Second, due to improper hydraulic pump installation, you may experience leaks from your hydraulic hoses and fittings.

- Third, if your tractor has been used for more than 15 hours per day or has more than 20 years of use on it, then you may be experiencing a worn piston seal that needs to be replaced for it operates efficiently again.

The following are some common hydraulic problems with John Deere 1025R tractors.

- No Lift Hydraulic Pressure

- Low Lift Hydraulic Pressure

- High Lift Hydraulic Pressure

- Poor Lifting Performance (slow or no lift)

- Loss of Lifting Performance (slow or no lift)

- Loss of Lifting Performance with Partial Load (slow or no lift)

- Loss of Lifting Performance with Full Load (slow or no lift)

John Deere 1025r Complaints

John Deere 1025r Complaints

John Deere 1025r Reviews

- Not enough power to run the mower deck

- Poorly designed deck height adjustment

- Low-quality cutting deck

- Difficult to maneuver around obstacles

- Very poor engine performance

Conclusion

The above symptoms are given about the John Deere 1025R Tractor. Here you can learn how to diagnose and fix them by yourself if you have the proper tool, or if not, you should take your tractor to the nearest John Deere service center or the local facility. You will save money if you do a little diagnosis repair work by yourself.

Related Posts

Husqvarna Hydrostatic Drive Problems